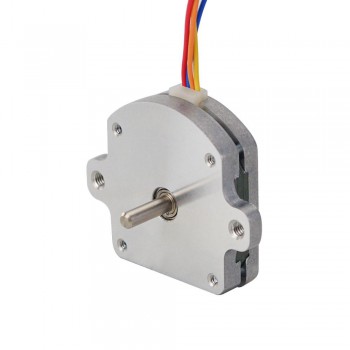

Design features and specific applications of pancake stepper motors

1.Working principle of pancake stepper motors

The working principle of pancake stepper motors is to convert electrical pulse signals into corresponding angular displacement or linear displacement. Whenever the motor receives an electrical pulse signal, the rotor will rotate a fixed angle in the set direction, which is usually called the step angle. The output angular displacement or linear displacement is proportional to the number of input pulses, and the speed is proportional to the pulse frequency.

2.Construction of pancake stepper motors

1.Stator: The stator is an important component of the pancake stepper motor, usually with small tooth-shaped magnetic poles and wound with coils. The magnetic poles of the stator will be magnetized after being excited by current to form a fixed polarity.

2.Rotor: The rotor consists of rotor 1, rotor 2 and permanent magnets. The outer ring of the rotor usually has small teeth, and the small teeth of rotor 1 and rotor 2 are staggered by a certain pitch in structure.

3.End cover: The end cover is used to close the two ends of the motor to protect the internal structure.

4.Rotor shaft: The rotor shaft is the support shaft of the rotor, responsible for transmitting torque and supporting the rotation of the rotor.

5.Front and rear plates: The front and rear plates are used to fix the structure of the motor and ensure the stable connection of the components of each part.

3.Design features of pancake stepper motors

1.Compact design: The pancake stepper motor adopts a flat design, which is easy to integrate into a compact system and minimize space requirements. For example, the frame size of some models is only 46 x 46 x 15mm, which is very suitable for application scenarios with limited space.

2.High torque performance: Pancake stepper motors generally have high torque output. For example, the Casun 1.7V pancake stepper motor provides a holding torque of 170mN.m, which is suitable for heavy-duty applications.

3.High precision: These motors generally have a small step angle, ensuring precise motion and control in various systems. For example, some models have a step angle of 0.9 degrees or 1.8 degrees, which enables high-precision motion control.

4.Energy efficiency: Pancake stepper motors operate at low voltage and low current, minimizing energy consumption. For example, some models operate at 1.7V and 0.5A, which is suitable for energy saving and cost-effectiveness considerations.

5.Reliability and durability: These motors usually provide a long warranty period, ensuring reliability and durability in use. For example, some models provide a warranty of 3 months to 1 year.

6.Customization options: Pancake stepper motors can be customized according to specific application needs, such as customizing the motor length to ensure seamless fit in various application scenarios.

4.Specific applications of pancake stepper motors

1.Robotics and automation equipment: Pancake stepper motors play an important role in robots and automation equipment. Due to their high precision, fast response and strong stability, they are often used in mechanical equipment that requires precise control.

2.Medical equipment: In medical equipment, pancake stepper motors can provide precise stepper control, ensuring stable operation and precise operation of the equipment. This makes it widely used in surgical instruments, diagnostic equipment and therapeutic equipment.

3.CNC machine tools: Pancake stepper motors have important applications in the field of CNC machine tool manufacturing. Because of its ability to directly convert digital pulse signals into angular displacement, it becomes an ideal actuator in machine tools that require high-precision control.

4.Printers: In printers, pancake stepper motors are used to move the print head position and feed the printing paper. This application requires the motor to have high precision and stability to ensure printing quality and efficiency.

5.Digital cameras: In digital cameras, pancake stepper motors control the lens to adjust the focus and brightness of the subject. This application requires the motor to provide tiny step control to achieve precise focus adjustment.

6.Air conditioning: In air conditioning systems, pancake stepper motors are used to move the shutters of indoor units, thereby changing the direction of airflow. This requires the motor to have fast response and high reliability.

7.Astronomical telescopes: In astronomical telescopes, pancake stepper motors are used to automatically search and track stars. This application requires the motor to have high precision and stability to ensure accurate star tracking.

Related articles:https://steppermotor1.livedoor.blog/archives/3083431.html

The working principle of pancake stepper motors is to convert electrical pulse signals into corresponding angular displacement or linear displacement. Whenever the motor receives an electrical pulse signal, the rotor will rotate a fixed angle in the set direction, which is usually called the step angle. The output angular displacement or linear displacement is proportional to the number of input pulses, and the speed is proportional to the pulse frequency.

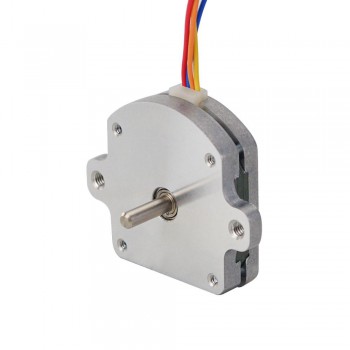

2.Construction of pancake stepper motors

1.Stator: The stator is an important component of the pancake stepper motor, usually with small tooth-shaped magnetic poles and wound with coils. The magnetic poles of the stator will be magnetized after being excited by current to form a fixed polarity.

2.Rotor: The rotor consists of rotor 1, rotor 2 and permanent magnets. The outer ring of the rotor usually has small teeth, and the small teeth of rotor 1 and rotor 2 are staggered by a certain pitch in structure.

3.End cover: The end cover is used to close the two ends of the motor to protect the internal structure.

4.Rotor shaft: The rotor shaft is the support shaft of the rotor, responsible for transmitting torque and supporting the rotation of the rotor.

5.Front and rear plates: The front and rear plates are used to fix the structure of the motor and ensure the stable connection of the components of each part.

3.Design features of pancake stepper motors

1.Compact design: The pancake stepper motor adopts a flat design, which is easy to integrate into a compact system and minimize space requirements. For example, the frame size of some models is only 46 x 46 x 15mm, which is very suitable for application scenarios with limited space.

2.High torque performance: Pancake stepper motors generally have high torque output. For example, the Casun 1.7V pancake stepper motor provides a holding torque of 170mN.m, which is suitable for heavy-duty applications.

3.High precision: These motors generally have a small step angle, ensuring precise motion and control in various systems. For example, some models have a step angle of 0.9 degrees or 1.8 degrees, which enables high-precision motion control.

4.Energy efficiency: Pancake stepper motors operate at low voltage and low current, minimizing energy consumption. For example, some models operate at 1.7V and 0.5A, which is suitable for energy saving and cost-effectiveness considerations.

5.Reliability and durability: These motors usually provide a long warranty period, ensuring reliability and durability in use. For example, some models provide a warranty of 3 months to 1 year.

6.Customization options: Pancake stepper motors can be customized according to specific application needs, such as customizing the motor length to ensure seamless fit in various application scenarios.

4.Specific applications of pancake stepper motors

1.Robotics and automation equipment: Pancake stepper motors play an important role in robots and automation equipment. Due to their high precision, fast response and strong stability, they are often used in mechanical equipment that requires precise control.

2.Medical equipment: In medical equipment, pancake stepper motors can provide precise stepper control, ensuring stable operation and precise operation of the equipment. This makes it widely used in surgical instruments, diagnostic equipment and therapeutic equipment.

3.CNC machine tools: Pancake stepper motors have important applications in the field of CNC machine tool manufacturing. Because of its ability to directly convert digital pulse signals into angular displacement, it becomes an ideal actuator in machine tools that require high-precision control.

4.Printers: In printers, pancake stepper motors are used to move the print head position and feed the printing paper. This application requires the motor to have high precision and stability to ensure printing quality and efficiency.

5.Digital cameras: In digital cameras, pancake stepper motors control the lens to adjust the focus and brightness of the subject. This application requires the motor to provide tiny step control to achieve precise focus adjustment.

6.Air conditioning: In air conditioning systems, pancake stepper motors are used to move the shutters of indoor units, thereby changing the direction of airflow. This requires the motor to have fast response and high reliability.

7.Astronomical telescopes: In astronomical telescopes, pancake stepper motors are used to automatically search and track stars. This application requires the motor to have high precision and stability to ensure accurate star tracking.

Related articles:https://steppermotor1.livedoor.blog/archives/3083431.html