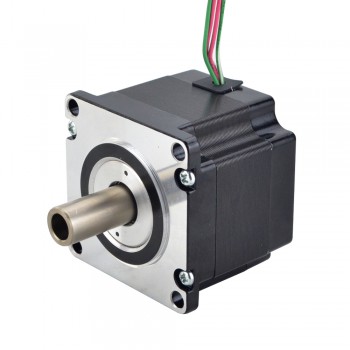

Design principles and applications of hollow shaft stepper motors

1.A brief introduction to hollow shaft stepper motors

Hollow shaft stepper motors are a specially designed stepper motor whose core feature is that they have one or more hollow shafts. These hollow shafts not only allow other parts of the motor to pass through, but also integrate additional functions as needed, such as heat dissipation and connection to other devices. The definition and application scenarios of hollow shaft stepper motors make them perform well in situations where precise positioning and synchronous control are required, such as automated production lines, robot arms, and medical devices.

2.Construction details of hollow shaft stepper motors

1.Stator: There are multiple coils on the stator. When the current in the wire coil changes, a magnetic field is generated around it. This magnetic field generates a force on the nearby coils, causing the coil to move. The design of the stator enables the motor to control the rotation of the rotor through the law of electromagnetic induction.

2.Rotor: The rotor is a hollow structure with multiple magnetic poles inside. The outer ring of the rotor is composed of multiple small teeth, which interact with the coils of the stator to achieve the rotational motion of the motor. The design of the rotor enables the motor to achieve high-precision position control and high-speed rotation.

3.Design principles of hollow shaft stepper motors

1.Bearing design: Bearings are an important part of hollow shaft motors, and their design needs to consider factors such as speed, load, radial and axial forces. Ensure that the bearings can withstand the operating load of the motor and maintain long-term stable operation.

2.Insulation design: The insulation design of hollow shaft motors needs to meet specific insulation levels, pressure tests, and partial discharge requirements. This ensures that the motor will not be damaged due to electrical failures during long-term operation, ensuring the safety and reliability of the motor.

3.Heat dissipation design: Since stepper motors generate heat during operation, it is necessary to design the heat dissipation system reasonably. Select appropriate heat dissipation materials and heat dissipation methods to prevent the motor from overheating and ensure that the motor runs at a suitable temperature, thereby extending its service life.

4.Hollow structure design: The design feature of the hollow shaft stepper motor is that it has a hollow hole in the center of the shaft. This structure optimizes the mechanical design, facilitates wiring, reduces volume and weight, and reduces noise and cost. At the same time, the hollow structure facilitates the transmission of matter, signals and light, increasing the diversity of its application scenarios.

5.Material selection and processing technology: Select high-quality materials that meet the standards, and ensure the sealing and operating stability of the motor through fine processing technology. Various indicators such as noise, vibration and temperature need to be strictly controlled during the processing to ensure that the product meets the relevant specifications.

4.Application of hollow shaft stepper motors

1.Automated production lines and robotics: In automated production lines and robotics, hollow shaft stepper motors are used to accurately control the motion trajectory of the robot arm and improve operational accuracy and flexibility. In addition, they are also used in automated assembly lines to transfer gas or liquid through the hollow shaft hole to control the clamping force and operating force of the robot arm.

2.Medical devices: In the field of medical devices, hollow shaft stepper motors are widely used in surgical robots, rehabilitation equipment, etc., providing high-precision, smooth motion and position control. For example, surgical robots can pass optical fibers and other instruments through hollow shaft holes to perform surgical operations.

3.Optical equipment: In optical equipment, hollow shaft stepper motors pass optical fibers or optical fibers through hollow shafts for imaging and detection. For example, hollow shaft stepper motors are used in laser cutting machines to pass laser beams for cutting operations.

4.Laboratory equipment: In laboratory automation systems, hollow shaft stepper motors pass reagents, samples, or other substances through hollow shafts for liquid handling and distribution. They are also used in rotating platforms or sample turntables in laboratory equipment to pass optical fibers or sensor cables through hollow shafts for position control and measurement.

5.Other applications: In the field of smart homes, hollow shaft stepper motors can be used in control systems for smart door locks, smart curtains and other equipment to achieve automated control of equipment. In addition, in applications such as water pumps, ventilation equipment, booster equipment, small hydroelectric generators, and propellers, hollow shaft stepper motors reduce volume and weight, reduce noise, and improve equipment performance and efficiency through their unique hollow structure design.

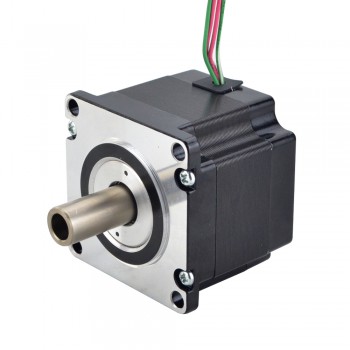

Hollow shaft stepper motors are a specially designed stepper motor whose core feature is that they have one or more hollow shafts. These hollow shafts not only allow other parts of the motor to pass through, but also integrate additional functions as needed, such as heat dissipation and connection to other devices. The definition and application scenarios of hollow shaft stepper motors make them perform well in situations where precise positioning and synchronous control are required, such as automated production lines, robot arms, and medical devices.

2.Construction details of hollow shaft stepper motors

1.Stator: There are multiple coils on the stator. When the current in the wire coil changes, a magnetic field is generated around it. This magnetic field generates a force on the nearby coils, causing the coil to move. The design of the stator enables the motor to control the rotation of the rotor through the law of electromagnetic induction.

2.Rotor: The rotor is a hollow structure with multiple magnetic poles inside. The outer ring of the rotor is composed of multiple small teeth, which interact with the coils of the stator to achieve the rotational motion of the motor. The design of the rotor enables the motor to achieve high-precision position control and high-speed rotation.

3.Design principles of hollow shaft stepper motors

1.Bearing design: Bearings are an important part of hollow shaft motors, and their design needs to consider factors such as speed, load, radial and axial forces. Ensure that the bearings can withstand the operating load of the motor and maintain long-term stable operation.

2.Insulation design: The insulation design of hollow shaft motors needs to meet specific insulation levels, pressure tests, and partial discharge requirements. This ensures that the motor will not be damaged due to electrical failures during long-term operation, ensuring the safety and reliability of the motor.

3.Heat dissipation design: Since stepper motors generate heat during operation, it is necessary to design the heat dissipation system reasonably. Select appropriate heat dissipation materials and heat dissipation methods to prevent the motor from overheating and ensure that the motor runs at a suitable temperature, thereby extending its service life.

4.Hollow structure design: The design feature of the hollow shaft stepper motor is that it has a hollow hole in the center of the shaft. This structure optimizes the mechanical design, facilitates wiring, reduces volume and weight, and reduces noise and cost. At the same time, the hollow structure facilitates the transmission of matter, signals and light, increasing the diversity of its application scenarios.

5.Material selection and processing technology: Select high-quality materials that meet the standards, and ensure the sealing and operating stability of the motor through fine processing technology. Various indicators such as noise, vibration and temperature need to be strictly controlled during the processing to ensure that the product meets the relevant specifications.

4.Application of hollow shaft stepper motors

1.Automated production lines and robotics: In automated production lines and robotics, hollow shaft stepper motors are used to accurately control the motion trajectory of the robot arm and improve operational accuracy and flexibility. In addition, they are also used in automated assembly lines to transfer gas or liquid through the hollow shaft hole to control the clamping force and operating force of the robot arm.

2.Medical devices: In the field of medical devices, hollow shaft stepper motors are widely used in surgical robots, rehabilitation equipment, etc., providing high-precision, smooth motion and position control. For example, surgical robots can pass optical fibers and other instruments through hollow shaft holes to perform surgical operations.

3.Optical equipment: In optical equipment, hollow shaft stepper motors pass optical fibers or optical fibers through hollow shafts for imaging and detection. For example, hollow shaft stepper motors are used in laser cutting machines to pass laser beams for cutting operations.

4.Laboratory equipment: In laboratory automation systems, hollow shaft stepper motors pass reagents, samples, or other substances through hollow shafts for liquid handling and distribution. They are also used in rotating platforms or sample turntables in laboratory equipment to pass optical fibers or sensor cables through hollow shafts for position control and measurement.

5.Other applications: In the field of smart homes, hollow shaft stepper motors can be used in control systems for smart door locks, smart curtains and other equipment to achieve automated control of equipment. In addition, in applications such as water pumps, ventilation equipment, booster equipment, small hydroelectric generators, and propellers, hollow shaft stepper motors reduce volume and weight, reduce noise, and improve equipment performance and efficiency through their unique hollow structure design.